|

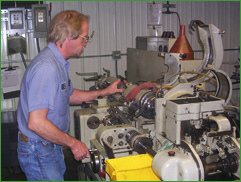

PTI has a full complement of both CNC Swiss and Swiss cam-driven automatic screw machines, both bar-fed and coil-fed, allowing us to economically produce your short-term run prototypes, as well as long running parts. Our CNC machines have up to 11 axes of control which yield the ability to make very complex parts complete on the primary machine, thereby reducing or eliminating the need for secondary operations. When necessary, our Secondary Department can do any machining (drill, mill, slot, grind, thread, etc) or finishing operations (plate, heat treat, etc.) required to complete the part. Most tooling is made in-house which allows for faster deliveries, especially in case of first orders or prototypes. Furthermore, we maintain, repair, and/or rebuild our equipment ourselves, therefore we are not at the "whim of a subcontractor" to get a critical job back up and running. PTI has a full complement of both CNC Swiss and Swiss cam-driven automatic screw machines, both bar-fed and coil-fed, allowing us to economically produce your short-term run prototypes, as well as long running parts. Our CNC machines have up to 11 axes of control which yield the ability to make very complex parts complete on the primary machine, thereby reducing or eliminating the need for secondary operations. When necessary, our Secondary Department can do any machining (drill, mill, slot, grind, thread, etc) or finishing operations (plate, heat treat, etc.) required to complete the part. Most tooling is made in-house which allows for faster deliveries, especially in case of first orders or prototypes. Furthermore, we maintain, repair, and/or rebuild our equipment ourselves, therefore we are not at the "whim of a subcontractor" to get a critical job back up and running.

|

|

|

|